Popular Keywords

- About Us

-

Research Report

Research Directory

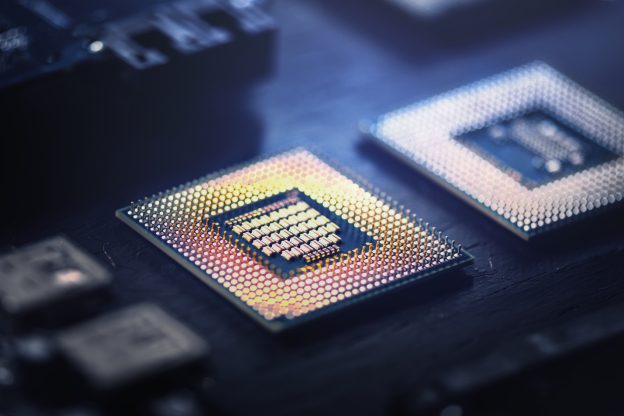

Semiconductors

LED

Consumer Electronics

Emerging Technologies

- Selected Topics

- Membership

- Price Trends

- Press Center

- News

- Events

- Contact Us

- AI Agent

Articles

News

[News] Samsung Reportedly Plans 1c DRAM Expansion for HBM4 in Hwaseong and Pyeongtaek by Year-end

As HBM4 has become the next battle ground for memory giants, Samsung seems to be aiming to close its gap with SK hynix through aggressive investment. According to ZDNet, Samsung plans to expand 1c DRAM (6th-gen 10nm-class) production in both Hwaseong and Pyeongtaek, with investments starting by year...

News

[News] Global Semiconductor CapEx Rises 27% in Q1, with Memory Spending Surging Over 50%

According to SEMI’s latest report, global semiconductor capital expenditures (CapEx) fell 7% quarter-over-quarter in Q1 2025 but rose 27% year-over-year, driven by sustained investments in advanced logic, high-bandwidth memory (HBM), and advanced packaging technologies that support AI applications...

News

[News] Google Teams Up with Alibaba-backed Xreal for Project Aura, Second Android XR Device

A decade after its rocky start with the first prototype of Google Glass in 2013, Google is making a strong comeback. At Google I/O 2025, the tech giant teamed up with China’s Xreal to launch Project Aura, a new Android XR device, according to Bloomberg and The Verge. The announcement, as per Bl...

News

[News] OpenAI Acquires Startup Co-Founded by Apple Design Icon Jony Ive in Ambitious AI Hardware Push

OpenAI will acquire io, an AI device startup co-founded by former Apple design chief Jony Ive, in an all-stock deal valued at nearly USD 6.5 billion, according to a report from Economic Daily News citing Bloomberg. The transaction marks OpenAI’s largest acquisition to date and signals its formal e...

News

[News] Qualcomm Back to the Data Center Market, with Related Oryon CPU Structure Expected to Unveil Later

U.S. chip giant Qualcomm held its COMPUTEX 2025 keynote speech on May 19, during which CEO Cristiano Amon announced the company’s re-entry into the data center market. While a detailed product roadmap has yet to be revealed, Amon believes Qualcomm is well-positioned for this move. With its recent ...

- Page 60

- 682 page(s)

- 3409 result(s)